Introduction

In today's competitive business landscape, companies are constantly seeking innovative ways to enhance productivity, reduce operational costs, and accelerate time-to-market. 3D printing technology has emerged as a game-changing solution that addresses all these needs simultaneously. This comprehensive guide explains how businesses can leverage 3D printing to boost customer productivity and gain a significant competitive edge.

Understanding the Productivity Benefits of 3D Printing

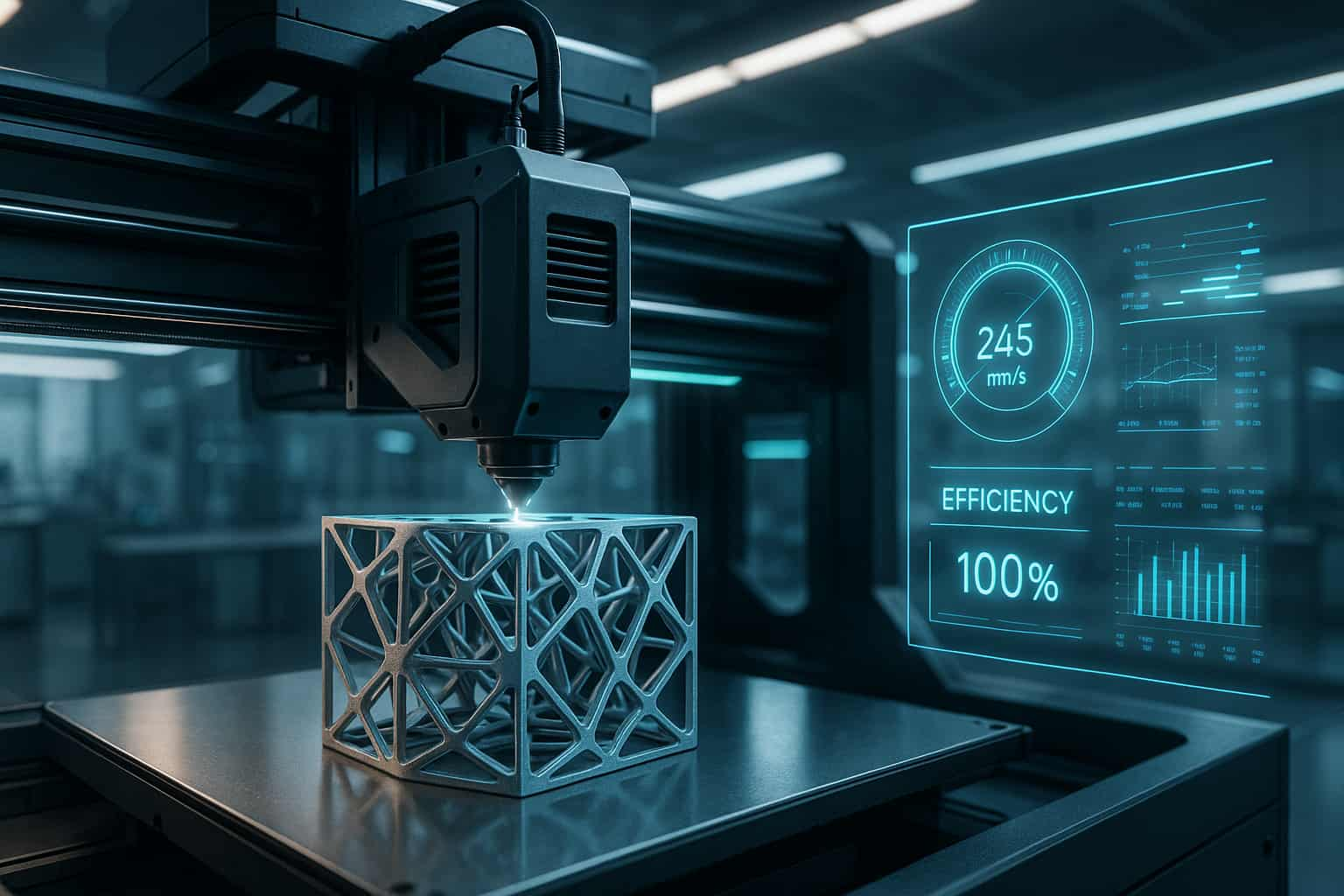

3D printing, also known as additive manufacturing, transforms traditional manufacturing by building objects layer by layer from digital designs. This method offers unmatched flexibility, efficiency, and speed - all of which contribute directly to productivity improvements.

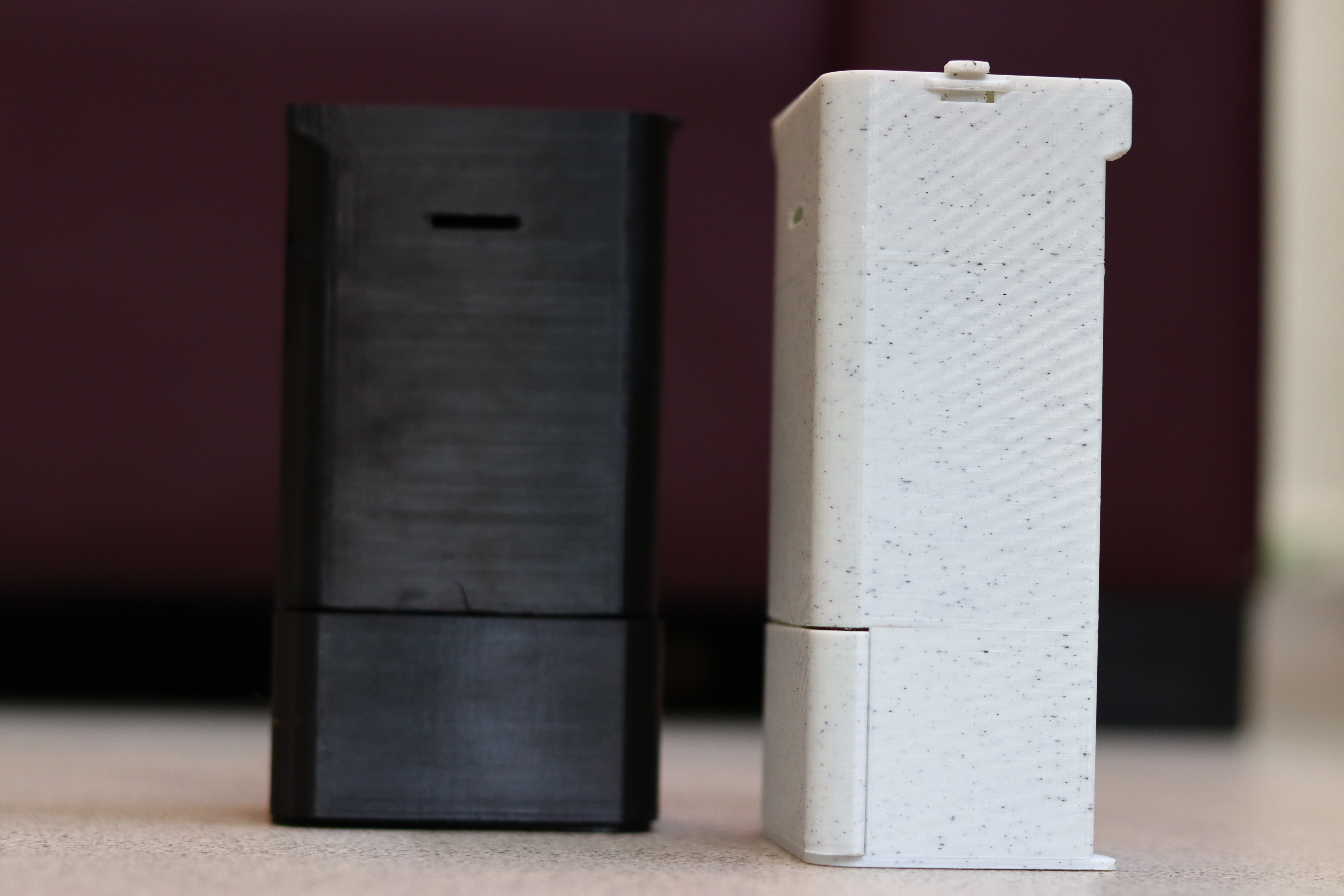

1. Rapid Prototyping and Product Development

Traditional prototyping can take weeks or months and requires costly tooling. With 3D printing, companies can:

-

Create functional prototypes in hours instead of weeks

-

Test multiple design versions quickly and affordably

-

Reduce product development cycles by up to 75%

-

Accelerate time-to-market

Practical Example:

An automotive parts manufacturer cut prototype development time from 6 weeks to just 2 days using 3D printing. They tested 15 design variations before selecting the final version, resulting in a better product and a much faster launch.

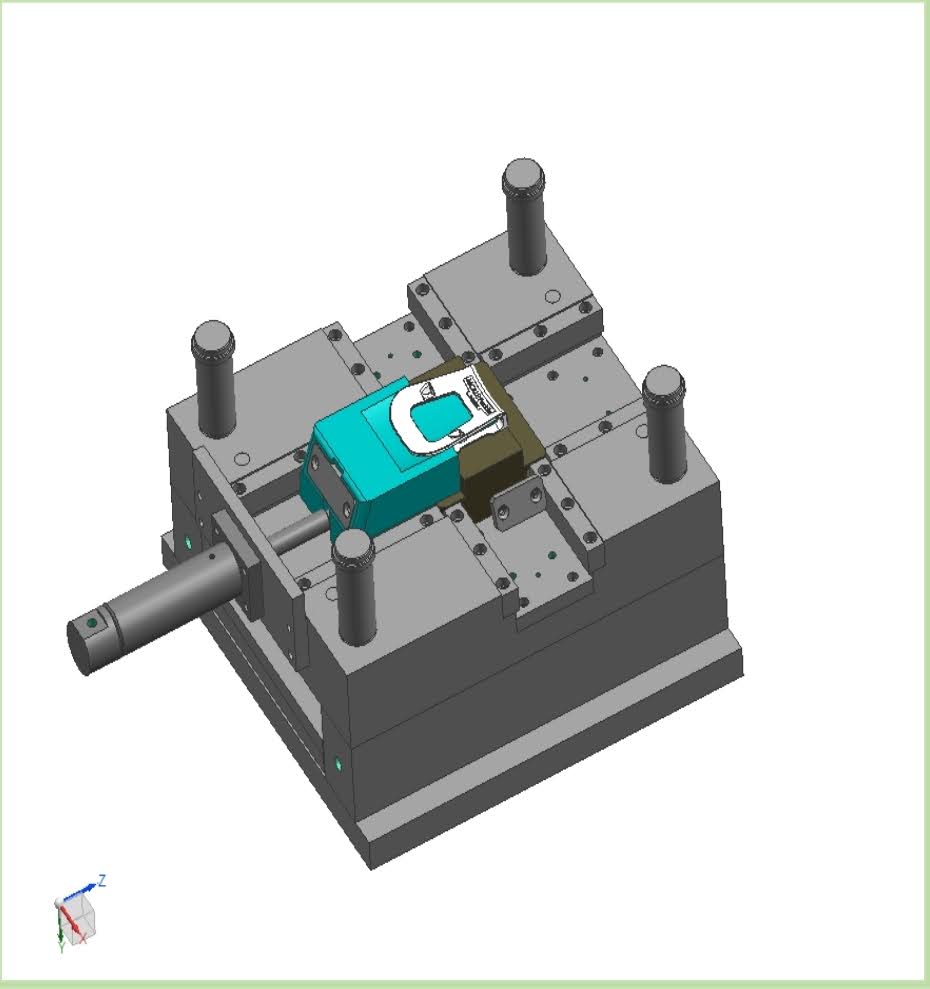

2. Cost Reduction Through On-Demand Manufacturing

3D printing removes several traditional manufacturing costs:

-

No need for expensive molds or tooling

-

Minimal material waste

-

Lower inventory costs through on-demand production

-

Reduced labor requirements for complex designs

-

No minimum order limitations

Practical Example:

A medical device company saved $500,000 yearly by 3D printing custom surgical instruments on-demand instead of maintaining large stock inventory. Material waste decreased by 90% compared to conventional manufacturing.

3. Customization at Scale

3D printing makes large-scale customization easy and cost-effective:

-

Personalized products for individual customers

-

Unique designs without retooling

-

Option to offer premium customization services

-

Faster response to customer preferences

Practical Example:

A dental lab improved productivity by 300% after shifting to 3D printing for dental crowns and aligners, producing each piece uniquely without additional setup time or cost.

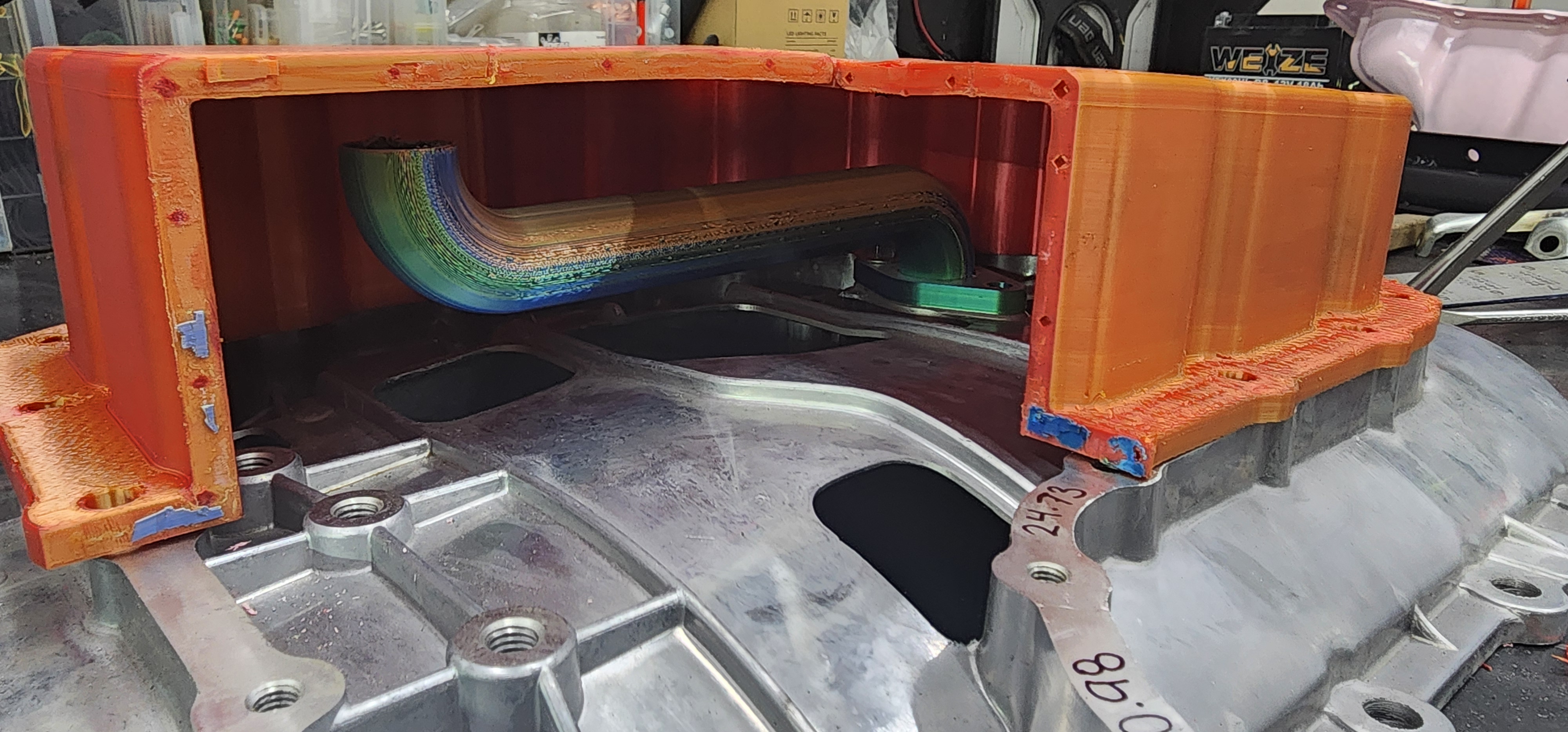

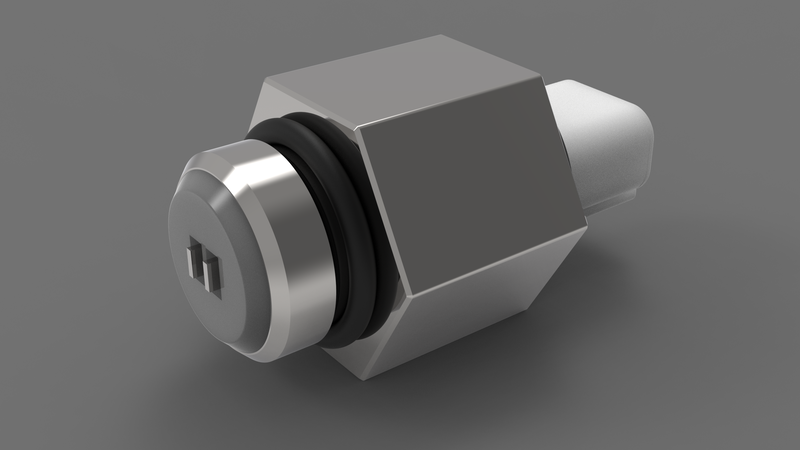

4. Complex Geometry and Advanced Design Freedom

3D printing enables businesses to produce complex shapes and internal structures that are impossible or extremely expensive to create traditionally:

-

Lightweight yet strong lattice structures

-

Internal channels for cooling or fluid flow

-

Combined assemblies printed as a single part

-

Organic, performance-optimized shapes

Practical Example:

An aerospace company used 3D printing and topology optimization to redesign a metal bracket, making it 65% lighter while maintaining strength. This single lightweight component saves thousands of dollars in fuel per aircraft annually.

5. Reduced Supply Chain Dependencies

With 3D printing, companies can shift to more flexible and localized manufacturing:

-

Print parts on-site or near their destination

-

Minimize shipping time and costs

-

Reduce supply chain risks

-

Enable automatic 24/7 production

Practical Example:

A global manufacturer installed 3D printing hubs on five continents, reducing part delivery time from 3 weeks to just 2 days and cutting logistics costs by 60%.

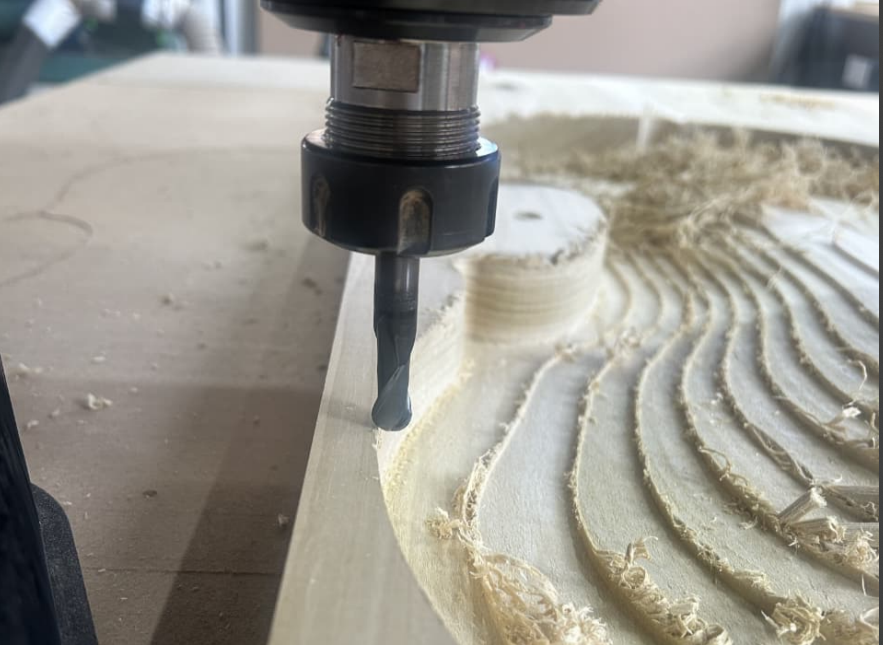

Implementation Strategies for Maximum Productivity

Start with High-Impact Applications

Focus on areas where 3D printing delivers immediate results:

-

Replacement parts to reduce equipment downtime

-

Custom jigs and fixtures for improving manufacturing speed

-

Rapid prototyping for research and development

-

Low-volume and custom products

Invest in Training and Expertise

To maximize benefits, your team should understand:

-

CAD design for additive manufacturing

-

Material selection and optimization

-

Post-processing methods

-

Quality control standards

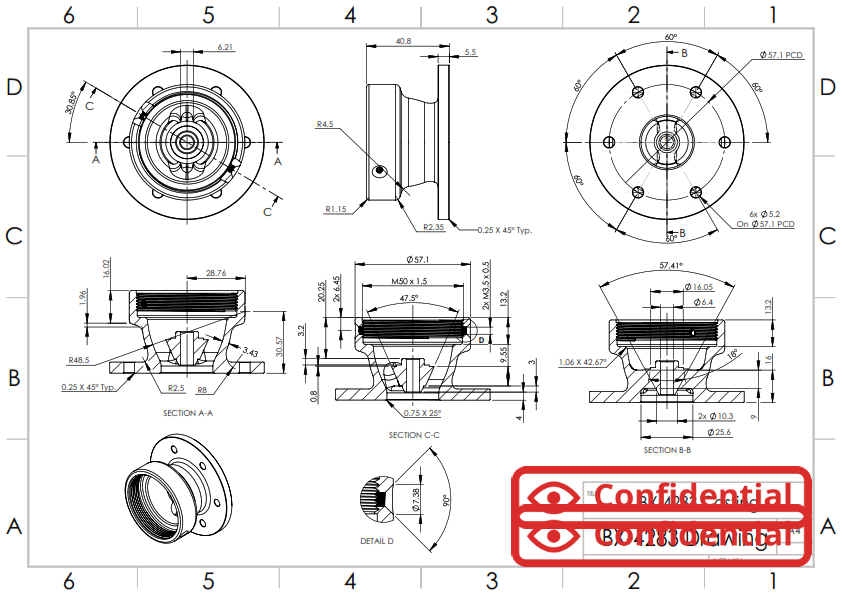

Choose the Right 3D Printing Technology

Select the technology based on your application:

-

FDM for functional prototypes and tooling

-

SLA/DLP for high-detail models

-

SLS for durable, production-grade parts

-

Metal printing for high-performance components

Measuring Productivity Improvements

Track the following metrics to evaluate your 3D printing success:

-

Reduction in prototype development time

-

Cost per part vs. traditional manufacturing

-

Number of design iteration cycles

-

Improvements in time-to-market

-

Inventory reduction percentages

-

Equipment downtime reduction

-

Customer satisfaction feedback

Conclusion

3D printing is transforming how businesses approach manufacturing, prototyping, and product development. It enables rapid iteration, lowers costs, allows large-scale customization, and removes traditional production limitations - all directly contributing to higher customer productivity.

The key to success lies in identifying high-value applications, investing in the right technology and training, and continuously tracking performance. As 3D printing becomes more advanced and accessible, the productivity benefits will continue to grow, giving businesses that adopt it early a strong competitive advantage.