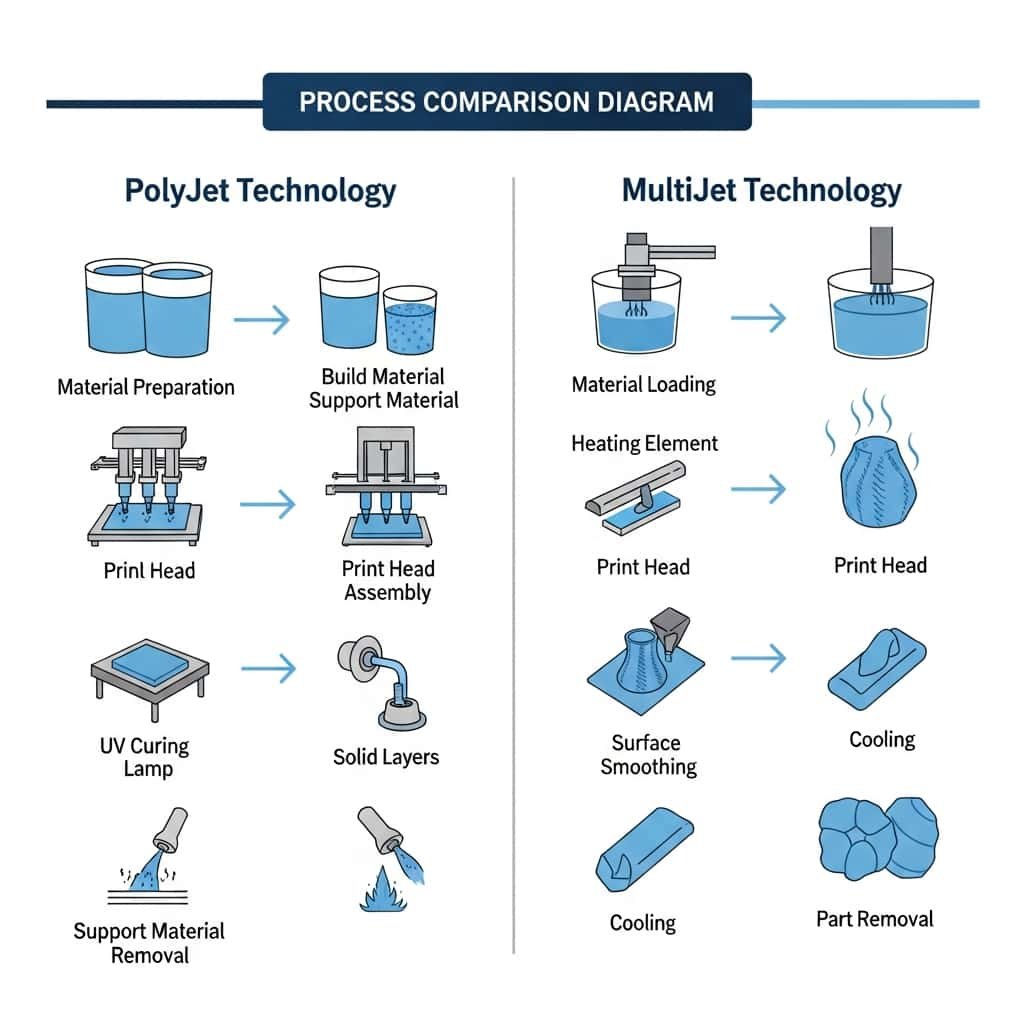

In the realm of additive manufacturing, PolyJet and MultiJet (MJP) 3D printing are two prominent methods that utilize photopolymers cured by ultraviolet (UV) light. Both technologies excel in creating high-quality prototypes and complex geometries, frequently finding applications in the dental and medical sectors-for example, in molds for crowns and braces. However, significant differences in their capabilities, materials, and production efficiencies influence their suitability for various applications. In this blog, we will explore these differences, enabling you to make informed decisions for your 3D printing needs.

What is PolyJet 3D Printing?

PolyJet printing was pioneered by Objet Geometries in 2000 and is now a core part of Stratasys’s offerings. This method operates similarly to an inkjet printer, where tiny droplets of photopolymer materials are jetted onto a build platform layer by layer. Each layer is then cured using UV light, achieving a high level of detail with layer heights as thin as 16 microns (though 25 microns is common for production).

PolyJet enables the simultaneous use of multiple materials within a single print job, allowing for the creation of parts with varied properties, such as combining flexible and rigid materials. This attribute makes PolyJet ideal for producing intricate prototypes but poses challenges in terms of part fragility and post-processing complexity.

Advantages of PolyJet

-

Multi-material capabilities: Ability to print parts with varying material properties in one job.

-

High detail and accuracy: Produces parts with exceptional surface quality and intricacy.

Disadvantages of PolyJet

-

Fragility of parts: Printed parts can be delicate and prone to breakage.

-

Longer post-processing times: The need for support removal typically makes this method slower than MJP.

What is MultiJet Printing?

MultiJet printing (MJP), developed by 3D Systems, also mimics an inkjet printer’s action but employs a distinct approach. In MJP, layers are built using UV-curable photopolymer or casting wax droplets. It can achieve layer thicknesses as small as 16 microns but lacks the extensive multi-material mixing capabilities of PolyJet.

Support structures in MJP are made from paraffin wax, allowing for easy post-processing; the completed prints can be softened and melted away in an oven or warm oil bath.

Advantages of MultiJet

-

Simplified post-processing: Wax supports melt away easily, streamlining the finishing process.

-

Cost-effectiveness for functional parts: MJP is well-suited for small to medium production runs.

Disadvantages of MultiJet

-

Limited aesthetics: Primarily produces single-color and single-material parts.

-

Potential for material property changes: Careful handling of post-processing is essential to maintain part integrity.

PolyJet vs. MultiJet: Direct Comparison

Key Attributes Overview

|

Attribute |

PolyJet |

MultiJet |

|

Uses photopolymer |

Yes |

Yes |

|

Capable of printing composites |

Yes |

No |

|

Easy post-processing |

No |

Yes |

|

Suitable for functional prototypes |

Yes |

Yes |

|

Small-to-medium production |

No |

Yes |

|

Requires support materials |

Yes |

Yes |

|

Capable of forming complex geometries |

Yes |

Yes |

|

Cost |

Higher |

Moderate |

Technology Comparison: PolyJet vs. MultiJet

Both technologies utilize UV-sensitive photopolymers for building parts, but they differ primarily in the configuration and number of print heads. PolyJet systems often feature two or more heads, allowing for more versatility in material composition, whereas MultiJet systems traditionally have a maximum of two.

Material Capabilities

PolyJet’s standout feature is its ability to create digital materials by combining multiple photopolymers to exhibit different mechanical properties within a single print. MultiJet printing, on the other hand, typically produces parts in a single color and material composition, restricting its application in projects necessitating complex material properties.

Applications of PolyJet and MultiJet

Both PolyJet and MultiJet cater to industries requiring high-precision parts, especially in the medical and dental fields. They excel in generating intricate prototypes for designs, enabling quick iterations throughout the development phase.

Print Volume Capacities

While print volumes may vary depending on specific models, PolyJet can achieve volumes up to 260 x 200 x 200 mm and MultiJet systems can reach up to 294 x 211 x 144 mm. Larger parts can be fabricated in segments and assembled afterward.

Surface Finish Comparison

Both PolyJet and MultiJet deliver smooth surface finishes due to their fine resolutions and layer thicknesses. However, complex geometries may occasionally exhibit rough surfaces, which can be remedied through appropriate post-processing techniques.

Alternatives to PolyJet and MultiJet

Digital Light Processing (DLP)

DLP is another form of 3D printing that employs liquid photopolymers cured by a projector. Unlike PolyJet and MultiJet, DLP builds parts upside down, submerged in a tank of photopolymer. This method rivals both PolyJet and MultiJet in resolution and cost-effectiveness.

Comparing PolyJet and SLA

Stereolithography (SLA) is another viable alternative, offering higher resolutions than PolyJet for functional prototypes and parts. SLA is also effective for creating tooling, molds, and detailed textured surfaces.

Comparing MultiJet and Multi-Jet Fusion (MJF)

Multi-Jet Fusion (MJF) is an alternative to MultiJet as it excels in producing complex geometries with outstanding surface finishes, utilizing polymer powder and a fusing system.

Frequently Asked Questions

-

What are the significant alternatives to PolyJet and MJP?

-

Alternatives include DLP, SLA, and MJF.

-

What are the differences between PolyJet and SLA?

-

SLA offers higher resolution and can produce molds and textured surfaces.

-

What distinguishes MJP from MJF?

-

MJF utilizes polymer powder and a fusing system, while MJP employs photopolymer droplets, focusing on resin-based solutions.

Conclusion

In the world of 3D printing technologies, both PolyJet and MultiJet have distinct advantages and limitations. Understanding their capabilities will empower you to choose the right technology for your prototyping and production requirements. Whether you need multi-material designs or streamlined post-processing, evaluating the nuances between PolyJet and MultiJet will lead to better outcomes in your projects.